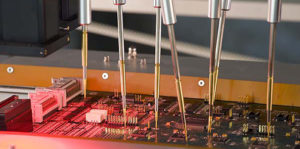

Flying Probe Test Sistemleri

Video : Acculogic FLS980

Flying Scorpion FLS980Dxi “The Ultimate Probing Machine”

Our flagship products, the FLS900™ Series of Flying Probe testers, ICT7000™ In-circuit tester and ScanNavigator™ Boundary Scan test suite, help ensure that tomorrow’s technologies don’t outpace today’s test capabilities. These products are highly advanced, scalable solutions made to solve a wide range of test challenges. Acculogic’s systems are made to accommodate a variety of applications and customers. At the core of our high-performance test systems lay the technologies needed to counteract next-generation test challenges.

Our flagship products, the FLS900™ Series of Flying Probe testers, ICT7000™ In-circuit tester and ScanNavigator™ Boundary Scan test suite, help ensure that tomorrow’s technologies don’t outpace today’s test capabilities. These products are highly advanced, scalable solutions made to solve a wide range of test challenges. Acculogic’s systems are made to accommodate a variety of applications and customers. At the core of our high-performance test systems lay the technologies needed to counteract next-generation test challenges.

Tight quality control measures together with time to market pressures are compelling manufacturing companies to choose effective yet lean test and quality assurance strategies in their production processes. Flying probe testers require no test fixtures, have few restrictions on board access, and can test boards with virtually unlimited number of nets. They also allow developers to complete test programs in a short time. For these reasons and more, flying probe testers have become indispensable tools in today’s electronic manufacturing.

Application of new and innovative design features to increase test speed, board access, reliability, and repeatability, have opened up new possibilities for deployment of Acculogic’s FLS900 series testers. As the first patented flying prober with double sided testing and 22 interchangeable probe modules, the FLS980Dxi is leading the way in defining new leaner and more efficient deployment models for production environments.

Key Features:

- Full Function Double Sided System

- Closed Loop AccuFast™ Drive System with ±0.1 Micron resolution

- Configurable with up-to 22 Closed Loop Flying Probes

- Programmable probe angle +6º to -6º degrees

- Extensive electrical Test capabilities including Analog, Digital, Mixed signal and Boundary Scan as well as advanced Optical and Thermal inspection

- Power-on and advance function testing (up-to GHz range)

- Up-to 128 non-Mux test channels through fixed nails

- Latent open detection

- Reverse Engineering

- Support for largest boards up-to 41″x 25.5″ (1050 x 640mm)

ACCESS

Shrinking component sizes and denser chip scale packaging technologies are posing new challenges to test engineers. Test pads, traditionally installed on PCBs, are being eliminated from many designs thus reducing physical access. Flying Probers are required to operate with unprecedented precision in order to meet the new challenges. FLS980 uses highly repeatable closed loop linear motor drives and joystick-like variable angle probe modules to maximize physical access and guarantee repeatable probing of fine pitch devices and small components like 0201, 01005s. FLS980 offers double-sided probing and up to 22 probe modules on both sides of the Unit Under Test (UUT) to facilitate efficient single pass testing.

Shrinking component sizes and denser chip scale packaging technologies are posing new challenges to test engineers. Test pads, traditionally installed on PCBs, are being eliminated from many designs thus reducing physical access. Flying Probers are required to operate with unprecedented precision in order to meet the new challenges. FLS980 uses highly repeatable closed loop linear motor drives and joystick-like variable angle probe modules to maximize physical access and guarantee repeatable probing of fine pitch devices and small components like 0201, 01005s. FLS980 offers double-sided probing and up to 22 probe modules on both sides of the Unit Under Test (UUT) to facilitate efficient single pass testing.

ACCURACY

Due to its modular and scalable architecture, the FLS980 guarantees superior probing precision and repeatability. Precise Closed Loop planar linear motors (shuttles) with “AccuFast™ Drive System” (±0.1 micron positioning resolution) independently move probe modules and cameras. The probe modules utilize equal-length identical probes to contact target points on the UUT. Each probe module is able to set the probing angle from 0º to 6º from vertical in any direction. The combination of shuttles’ positioning and joy-stick like probe motion ensures unmatched accessibility to points on the UUT. You can now test boards whose layout, size, and technology defy testing on traditional in-circuit and other moving probe testers.

FLS980Dxi system architecture ensures repeatability

- Closed Loop Drives for shuttles and probe modules ensure precise and repeatable positioning of the probes.

- Riding on 12 micron air gap, shuttles travel free of friction and with no mechanical contact on the stator plane and therefore operate free of wear.

- High resolution fiducial detection cameras, precise lighting, and advanced image processing software ensure precise and repeatable detection of fiducial marks on the UUT as well as correct compensation for any offsets.

- The electronic measurement system relies on precision circuits and components for reliable and repeatable measurements.

- Integrator Pro™ system control software with sophisticated motion control and measurement algorithms ensures robust and repeatable operation.

PROBING ANGLE

Warping of printed circuit boards is a common issue that should be taken into account in SMT board assembly, inspection and test processes. During Flying Probe test, board warp changes the physical position of target points by an offset. When probing angle is 0 degrees from vertical, board warp will cause no probing errors, however, as the probing angle increases, the probing error also increases. A 0201 chip on a board with 0.5 mm warp using 15 degree probing angle cannot be probed dependably. Decreasing probing angle to 3 or 4 degrees reduces warp related uncertainty, and leads to reliable probing. Offering optimum probing, FLS900’s Advance probe modules rely on a patented design to probe target boards Omni-directionally on the horizontal, and -6 to +6 degrees on the vertical planes. As probing angle increases the probe slippage factor increases. Probe slippage can lift pads and vias and leave unacceptable marks on the target.

Probe Module Types

The FLS900 systems can be configured with up-to 22 Probe Modules on top and bottom side to ensure maximum access and optimum test time. There are two types of probe modules available for the system:

- Basic Probe Module BMP 700 with fixed angle (+6°)

- Advanced Probe Module APM 800 with programmable angle ( 0 to +6°)

System can be configured with mix of the variable and fixed angle probe modules.

The flying probe drive systems has a positioning accuracy of 0.1 micron which provides reliable probing of target sizes as small as 75 microns ( 3 mils) in production environment. To probe even smaller targets in special applications Acculogic provides higher precision probe modules and cameras as future upgrades.

Probe Module Specifications:

- 3D Programmable Angle 0° – 6° (+6° for fixed angle)

- Programmable Speed 15 – 1500 mm/s

- Programmable Pressure 0.5 – 3.0N

- Choice of Probe Tip Radius 50 µm – 500 µm

- Choice of Probe Tip Styles Needle, cup, dome

- Max Probing Height 42mm

- Maximum component Height 85mm.

SPEED

Test time on Flying Probe depends mainly on the number of test steps and speed of probe movement. Shorts Test consume a large part of overall test time. FLS980’s flexible measurement system provides a host of test strategies including Boundary Scan (JTAG) and NetScan™ to significantly reduce test time without impacting test coverage or repeatability. In addition AccuFast™ Closed Loop Drive system boosts speed and acceleration by 4 times over open loop systems.

Key Features of AccuFast Drive System™

- Significantly faster than open loop systems (4x)

- High acceleration (4x)

- Enhanced probing accuracy

- Three times better dynamic response +/- 1 degree rotation

- Automatic orthogonality between X and Y axis

- Sensorless homing (no adjustments)

- DSP based motor controller

- Built-in linear and parabolic interpolation (more efficient shuttle movements)

- Low energy usage (50% reduction)

PATENTED MULTI-PROBE SYSTEM

The FLS980 has a modular architecture that is expandable to 22 probes. The probe modules have easily interchangeable probe tips. A range of probe tip styles are available off the shelf. In addition to providing excellent test coverage on densely populated circuit boards, this flexibility makes the FLS980 an ideal solution for testing backplanes where direct contact with connector pin tips is required.

FLS980 systems can be configured with Acculogic’s patented Mini-Flying Fixture which provides the functionality of a small bed-of-nail access in the flying probe system, i.e. “Flying Fixture”. This customizable Probe Module can be used in functional testing, digital, boundary scan (JTAG) testing and more. Its low cost and flexibility makes Flying Mini-Fixture an indispensible addition to the system.

MEASUREMENT SYSTEM

High speed (up-to 1000 measurements/sec) and precision analog measurement system provides 4-wire measurements capability for all 22 flying probes (top and bottom side). All probes can perform in-circuit tests as drivers, sensors, or guards on discrete and integrated analog/ digital components. Analog component testing including resistors, capacitors, inductors, diodes, Zeners, transistors, FETS, thyristors, opto-couplers, switches, trimmers, relays, fuses and connectors is available on the FLS900. These include 2-wire and 4-wire tests, device ON and OFF tests using two sets of separately available stimulus/ measurement resources. Also, power-on testing for voltage regulators and operational amplifiers are possible using the voltage measurement module.

SOFTWARE

Integrator Pro Features:

- Automatic program generation software

- Built-in Boundary Scan (JTAG)

- Automatic multi-level guard assignment

- QuickTest™ for quick test program development

- Auto-debug (unattended)

- Test Sequence with logical flow control

- Interactive board description editor add/modify test points, package etc.

- Panelization support

- Program and motion optimization

- Powerful Script language for functional and advance testing

- Test coverage report generation

- Statistical Process Control (SPC)

- RepairMatic™ graphical repair station software

Test program generation for FLS900-series testers is highly automated, simple, and intuitive. The process starts by using the XMatic™ software to translate UUT data from any of the 35-plus commonly used CAD formats. CAD data is merged with the Bill of Materials, and other relevant information to create an output file that contains data elements required to automatically generate test programs.

Integrator Pro™ is the automatic test program generator (ATPG) and operating software that manages all aspects of test program sequencing, debugging, optimizing, and execution on the Flying Scorpion. The IntegratorPro also manages all physical resources of the tester including motion, vision, electrical stimulus and measurement. Integrator Pro supports many different plug-in modules such as Boundary Scan, BodeScan and FlashScan etc. which enhance test coverage and increase execution speed. An easy-to-use scripting language opens up internal resources of the tester, providing users with maximum flexibility to write complex test protocols with simultaneous use of multiple probe modules.

The Integrator Pro is also equipped with an impressive set of tools for statistical process control, test execution flow management, and test coverage report generation. Interfaces to automatic repair processes, and automatic test program management (version control) are available.

BodeScan™

BodeScan™ is a unique built in network analyzer that extends the system fault coverage to small value resistors, capacitors, and inductors in complex networks found on RF boards.

VECTORLESS TEST

PinScan™ Patented Open Pin Detection suite

PinScan is a complimentary suite of analog and digital test techniques for detecting Opens on ICs, including BGAs, as well as connectors and polarized capacitors.

- CScan™ is a patented technique used in vectorless testing of ICs and connector pins. CScan is used to test open pins as well as the polarity of electrolytic capacitors. CScan functionality detects open pins on devices located on the top and/or bottom side of the board.

- ChipScan™ is a patented 3-pin technique for vectorless open testing on digital IC pins. It exploits the parasitic diodes/transistors in each digital IC, and tests each pin for open faults. Power up is not required in order to use ChipScan. This method is particularly useful where bus structures are used. ChipScan detects wire bonding defects, open pins and cold joints. ChipScan functionality is available on all probes covering top and bottom side of the unit under test.

- ScanProbe™ is a digital technique that uses flying probes to detect opens on digital IC pins of devices that are IEEE-1149.1(JTAG) compliant. ScanProbing is fast and repeatable, uses the digital and boundary scan capability of the FLS900 for fault detection.

- Active CScan™ combines the coverage of CScan with the power of Boundary Scan. It draws the best from each technology to increase the test coverage and reduce the test time therefore enhances overall capability of Flying Scorpion

- ThermoScan™ uses the mechanical capability of its flying probe to automatically move an infrared temperature sensor over the PCB to measure the powered PCB temperature pattern. This new test method bridges the gaps between conventional test technologies.

ThermoScan™ can be used at every stage of the production process. It can be used for design verification and helps to optimize the thermal distribution. This will increase the mean time between failures (MTBF) for products in the field, decreasing warranty cost. It also can be used to efficiently repair PCBs returned from the field. ThermoScan™ quickly provides useful troubleshooting information, dramatically reducing repair time.Acculogic’s ThermoScan™ can measure and analyze the thermal behaviour of single-sided and double-sided PCBs. The systems’ temperature range is from -18 to 220°C with a measurement accuracy of 3 percent.The PCB Operation involves the flow of electrical current, which produces heat when passing through a circuit having resistance. The temperature pattern on an operating IC, or assembly can be a good, repeatable indication of its operational status.

ThermoScan™ can be used at every stage of the production process. It can be used for design verification and helps to optimize the thermal distribution. This will increase the mean time between failures (MTBF) for products in the field, decreasing warranty cost. It also can be used to efficiently repair PCBs returned from the field. ThermoScan™ quickly provides useful troubleshooting information, dramatically reducing repair time.Acculogic’s ThermoScan™ can measure and analyze the thermal behaviour of single-sided and double-sided PCBs. The systems’ temperature range is from -18 to 220°C with a measurement accuracy of 3 percent.The PCB Operation involves the flow of electrical current, which produces heat when passing through a circuit having resistance. The temperature pattern on an operating IC, or assembly can be a good, repeatable indication of its operational status.

INTEGRATED BOUNDARY SCAN

Features:

- Fully integrated hardware and software

- IEEE1149.1 and IEEE 1149.6 supported

- Support for multiple scan chains up-to 8

- Scan and non-scan testing

- Automatic test optimization

- Automated test generation and intelligent diagnostics

Boundary scan (JTAG) is a test methodology based on IEEE 1149.1 standard. Compliant Semiconductors, when installed on a circuit board, allow the interconnecting nets and digital clusters such as memory devices to be tested on the FLS900. Furthermore, Boundary Scan offers a comprehensive board-level protocol for programming flash and other programmable devices.

Integration of boundary scan with flying probe systems is no longer an option but a requirement since the combined strategy improves test coverage and test time.

Boundary scan is an integral part of the FLS900; digital test patterns generated by Acculogic’s powerful ScanNavigator software are delivered to the UUT through Probe Modules or board carrier system. FLS900 goes beyond interconnect testing by providing full digital test capability when and where needed. This technological break-through is made possible by merging

Acculogic’s two powerful software suites, the “Integrator Pro” and the “ScanNavigator”. [/read]